Today, begin with a 90-day embodied-carbon audit across products; publish a highly-edited γεγονότα sheet with targets; set a 25% reduction in lifecycle emissions within three years; pilot modular components to enable easy upgrades.

Under supplier contracts, favor regional materials, recycled content up to 40% for interiors; specify low-impact sources with transparent declarations; aim to cut transport miles by 50% through local networks.

Look at progress dashboards; post quarterly updates on internal channels; maintain a twitter presence for public updates; increasing transparency satisfies the needs of many companies, their stakeholders, regulators.

This approach stands as a model that delivers good returns; a figure such as 40% recycled content offers cost benefits; the future looks promising; the potential is high.

Hard-won governance supports the ικανότητα to react to market signals; assign clear roles; this reason explains why their buy-in matters; results adds resilience; the ποτέ-improving loop yields value.

Today, many companies spend resources evaluating lifecycle performance; post projects that show ROI; viewing data drives decisions; future value appears clear.

Greenline: Practical Pathways for Sustainable Design

Adopt modular assemblies, long‑life materials to cut waste by up to 35% over two decades; keep upgrades straightforward, maintain performance, reduce power demand, doing more with less.

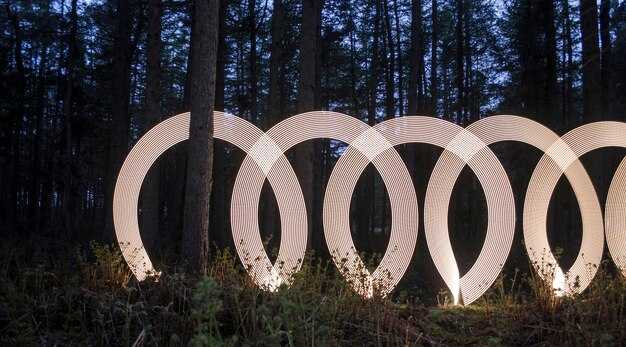

Specifically harnessing daylight outside via a simple technique lowers peak power; an explainer, a handful of images show how the outcomes appear as the viewer scroll.

Reports across projects reveal a number of lessons; available options include breathable envelopes, shading controls, low‑emission finishes, offering advantage for retrofits; shot logs help track progress.

Stories gathered on sites provide a place for viewer‑focused narratives; a story of adaptation appears in practice; sharing results helps maintain this matter, giving reason what works for doing.

Low-Carbon Material Sourcing: a 4-step checklist for suppliers and products

Step 1: Pre-production planning; map streams of material types; define the purpose behind each choice; target a lower carbon footprint across millions of units; align with front line teams to prevent misalignments; maintain polished data trails for traceability; planning today sets clear direction.

Step 2: Material audits; require pre-production documentation detailing material type; supplier location; carbon intensity estimates; demand third-party verification; pull global reports; cross-check with independent labs; use google for quick checks; monitor twitter signals for credibility.

Step 3: Qualification framework; assess supplier capability; verify traceability levels; risk indicators; site visits before production starts; require life-cycle data covering raw material extraction; processing; transport; request third-party certification; maintain data pages for each subject material; align on logging standards; space for updates as streams shift.

Step 4: Implementation; ongoing monitoring; translate audit findings into policy; set performance dashboards; track carbon intensity per material type; maintain working relationships with suppliers; produce informative reports; turning insights into action today; keeping polished records; looking for opportunities to optimize lights, energy use, transport distances; though adjustments required.

Passive Design First: quick strategies to reduce energy use in early charrette

Start with a 60-minute solar map exercise for each massing option; adjust orientation to maximize daylight in winter, reduce overheating in summer.

Apply simple shading rules: overhangs sized for mid-season sun angles; shading screens that can be deployed during peak loads; glazing with low SHGC where hot climate.

Keep models lean; use daylight factor, sunlit hours as quick metrics; decisions appear in shared visuals.

Drive decision speed by presenting three concise options backed by daylight graphics; powerful visuals clarify tradeoffs.

Deliver a clear brief for clients; bring great visuals that customers can scan quickly.

Train the team to produce short videos that explain choices; animated diagrams show sun paths, thermal loads, comfort gains, often clear.

Focus on energy savings; achieve measurable results with orientation, envelope details, shading strategy; collect hard data.

Under busy schedules, many stakeholders benefit; share existing stories to illustrate outcomes.

Specifically, use a simple terms glossary in the table that clients can read quickly; ensure that each row shows figures. Examples exist: three micro options.

Example: three massing routes illustrate the approach; a quick recap helps drive conversions.

This article focuses on practical steps that drive results; not placeholders, real actions deliver value to clients, communities.

Use tiktoks style clips; add a short video to illustrate.

| Strategy | Focus | Expected reduction | Time burden |

|---|---|---|---|

| Solar orientation map | Daylight driven | Up to 20–30% | 60 min |

| Shading devices | Overhangs, screens | 10–25% | 30 min |

| Envelope control | Glazing select, insulation | 5–15% | 45 min |

| Air leakage check | Sealing emphasis | 5–10% | 15 min |

Design for Disassembly: guidelines for modularity and end-of-life planning

Recommendation: adopt a modular architecture that enables disassembly in seconds with standardized interfaces; use captive fasteners; employ reversible joining methods; publish an end-of-life plan in the product brief.

Guidelines for modularity and disassembly

- Step 1 – define module boundaries between core function blocks; each module has a single responsibility; this keeps complexity low; swapping modules remains isolated; modules designed to be swapped quickly; think in terms of clear interfaces and scalable blocks.

- Step 2 – standardize interfaces: fixed mechanical connectors; electrical plugs; reuse a single screw size across the family; ensures compatibility across generations; between modules, interfaces should be tactile, readable, and durable.

- Step 3 – material choices: select substances with high recyclability; target at least 90% by mass; tag components with resin codes, metal types for read access during sorting; include materials that support second-life reuse.

- Step 4 – joinery for disassembly: use captive fasteners, removable clips; avoid permanent bonds that hinder recovery; prefer reversible adhesives only when required; keep tools minimal for technicians in the field.

- Step 5 – labeling and documentation: print a compact bill of materials or provide a QR code linking to an end-of-life guide; this is crucial for second-life reuse or remanufacturing; keep it accessible today; published guides help readers understand both creation and lifecycle steps.

End-of-life planning

- Step 6 – plan reverse logistics early; contract with recyclers and refurbishers; set KPI: time to recover modules under 10 days; track performance in reports; include metrics such as material recovery rate and cost per module.

- Step 7 – maintain clear disassembly instructions for technicians; include required tools, safety notes; publish updates via a branded platform; ensure read access by partners; today these guides are published and publicly accessible; this helps market alignment across platforms.

- Step 8 – customer engagement: share modularity benefits through case studies; collect preferences and likes; invite feedback via ctas on product pages; incorporate input into new modules; between releases, capture insights to inform future creation.

- Step 9 – continuous improvement: iterate on module libraries; between revisions, integrate findings from reports; ensure compatibility across the branded ecosystem; this keeps the portfolio versatile for the world market.

Impact, measurement, and outreach

- Step 10 – metrics to track: disassembly time, recyclability percentage, second-life utilization; publish quarterly results; readers today expect transparent performance reports; this boosts trust in a world of branded products.

- Step 11 – content strategy: cutting-edge briefs on platforms such as tiktok; publish short readouts, visuals, and process snapshots; read metrics help optimize ctas; engaging audiences between posts increases engagement with the market.

Notes on execution

The approach engages suppliers, recyclers, and customers in creation of circular value; the process is likely to cut waste and cut reverse-logistics costs; when performance targets miss, adjust module boundaries and interfaces; readers can read published case studies to benchmark progress; the market rewards products designed for easy reuse; continue to iterate today to maintain a successful lifecycle; this plan keeps your branded ecosystem connected across platforms and complies with evolving requirements.

Transparent Narratives: how to present sustainability choices to clients and teams

Provide a main, straightforward briefing with three options; each option carries quantified impacts, trade-offs, plus quick testimonials: client voices, team stories.

- Quick wins: low disruption; high visibility; main metrics: energy use reduced; waste down; branded reach up; three-week cycle; deliverables: a single branded story; a step-by-step guide; videos watched; facts sheet; client voices; team quotes; hubspot dashboards; front-market distribution; targeted campaigns; topic resonance; quick gigs to pilot; teams consume less energy.

- Medium path: optimized operations; focus on supply chain tweaks; metrics: material usage down; lifecycle impact reduced; ROI; timeline: 8–16 weeks; deliverables: campaign kits; quick testimonials; topic map; hubspot dashboards; targeted campaigns; market ranks improvement; global resonance.

- Long-term transformation: systemic change; mission alignment; metrics: scope 3 emissions, consumer perception shift, ROI; timeline: 6–12 months; deliverables: branded narrative hub; story library; video modules; training sessions; targeted outreach; front-line teams briefed; testimonials collected; gigs to support rollout; ranks in market measured.

Guidance for teams: focus on relationships with clients; maintain a single, clear topic; keep the message branded; test with quick testimonial videos; rely on facts; use hubspot for targeted communication; track market ranks; ensure global relevance; monitor performance quickly; adjust based on real-time data; let the mission guide choices.

Good practice combines quantitative data with human narratives.

Supply Chain Verification: practical tips for certifications, audits, and traceability

Σύσταση: Create a written verification guide with five core steps; assign owners; establish a data schema; implement a shared platform such as hubspot for supplier profiles; define kickoff milestones.

Map five supplier categories by risk; identify root causes for delays; watch for changes in capacity, quality, or compliance; record each event in a traceable log; this log supports audits; certifications; traceability checks.

Before each external audit, assemble a polished dossier consisting of policy statements, training records, supplier self-assessments, plus evidence of corrective actions; use a structured template to accelerate reviewer review; this approach reduces cycle times; increases confidence.

Maintain a watch list of suppliers with rising risk; ensure traceability data is synchronized across ERP and WMS, with hubspot used for supplier profiles; this reduces information gaps; speeds remediation; five data points per product help to reproduce lineage quickly; link traceability to production output; teams quickly produce evidence during audits.

In practice, implement a quick-start plan with a 90-day sprint; publish a short video log (vlog) summarizing progress for internal teams; consider quarterly external assessments to validate the process; this approach increases transparency, drives continuous improvement.

Key measures: watch cycle time; capture this metric in dashboards; optimize processes to reach compliance faster; before shipments, verify data quality; use five-minute checks to confirm lot, origin, destination; this approach makes audits less twitch, more predictable; consumption insights from audio summaries help planning of future production runs.

Currently, monitor supplier performance in a quarterly digest; decided actions feed planning shifts.

Audience lens: provide a viewer-friendly digest; publish weekly audio notes; encourage quick feedback from internal teams; watch engagement rise as data quality grows.

Μια γραμμή από το Greenline – Βιώσιμες Τάσεις Σχεδιασμού και Καινοτομία">

Μια γραμμή από το Greenline – Βιώσιμες Τάσεις Σχεδιασμού και Καινοτομία">